Smart Warehouse With Automation Built-in

$1.8B+

Investments

with Long-Term Partners

10+

years of property development

& automation expertise

1,370,000+ sqm

years of property development

& automation expertise

$1.8B+

Investments

with Long-Term Partners

Step inside omega

Explore omega technology

as/rs moves 30,000

times per day

times per day

The AS/RS handles 30,000 pallet moves per day with 75–150x human efficiency and 99% accuracy, dramatically reducing errors.

Agv efficiency +50%

With 100+ AGVs equaling 200–300 workers, automated routing boosts overall efficiency by 30–50%.

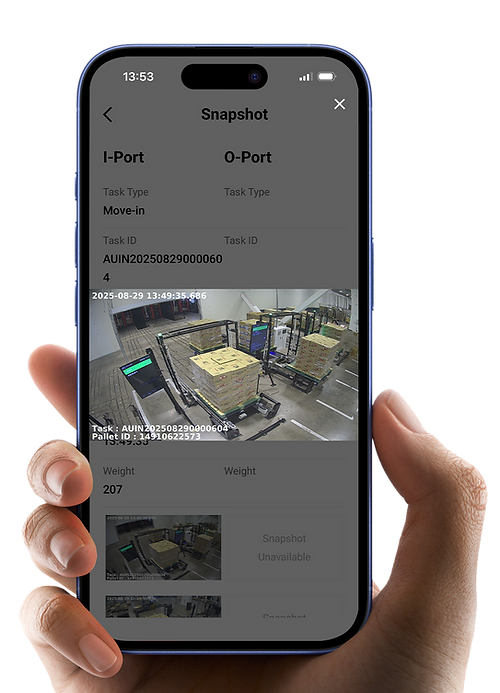

I/O-PORT 5x FASTER

I-Port/O-Port completes in/outbound in 1–2 minutes, 3–5x faster than manual work, with 24/7 multi-level operations beyond traditional limits.

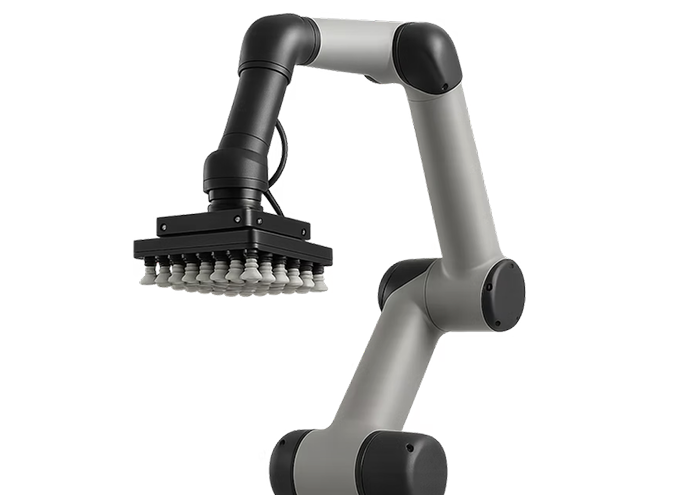

ROBOTIC ARM 99%+

ACCURACY

ACCURACY

Robotic arms pick 600–800 items per hour, 4–6x faster, with 99%+ accuracy to reduce errors.

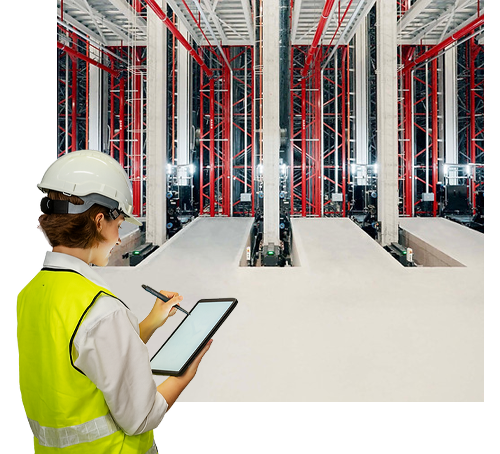

ALPOS ONE SYSTEM,

DRIVING ALL

DRIVING ALL

ALPOS connects AS/RS, AGVs, IPort/OPort, and robotic arms into a fully integrated smart system, enabling real-time monitoring and scheduling for zero-delay operations, while consolidating warehouse data to optimize routing and resource utilization.

DIGITAL APPLICATION

DIGITAL APPLICATION

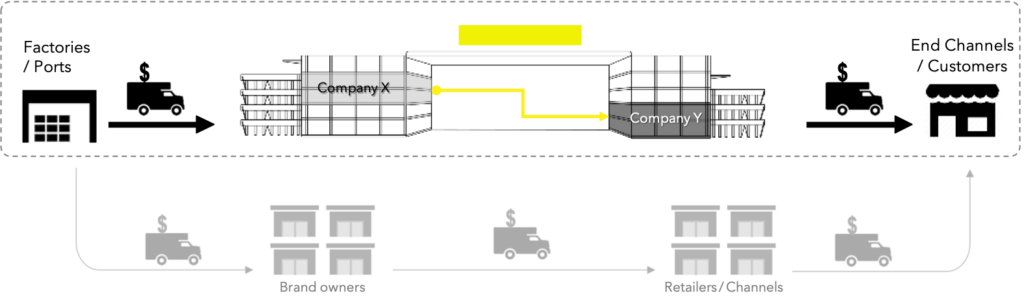

Via Cluster Effect and Digitalization

STOCK COUNT

IT PLATFORM: ALPOS

DIGITAL TWIN

SIMULATION FOR FUTURE FORECASTS

By combining digital twin models with big-data analysis of past customer demand patterns and fluctuation frequencies, we are able to forecast changes in customers’ future operations and evaluate automation performance.

Predict. Simulate. Optimize.

Real-time logistics drives real-time sales.

TRANSPARENCY

DATA TRANSPARENCY

Voice of customer

Ally Transport

General Manager

Ricky Lin

How ASC Transformed the Human-Dependent Logistics Model with OMEGA

Dematic Director of Business

Cooperation Asia & China

Cindy Huang

Standardization and System Integration Are Now Essential to Drive Smart Logistics

Murata L&A Sales

Department Senior Manager

Hiroshi Hasegawa

The Key Driver of Logistics Automation Is Now Shifting from Cost Control to Labor Shortages, Especially in Japan

Ally Logistic Property Senior Vice President

Hsinming Huang

Ally Logistic Property Smart Logistics Technology Assistant Vice President

Vincent Hsieh

How ASC Transformed the Human-Dependent Logistics Model with OMEGA

Omega various

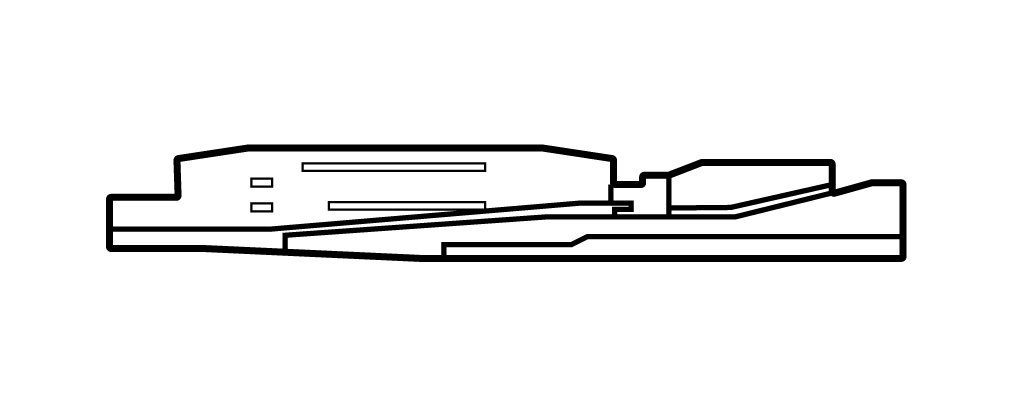

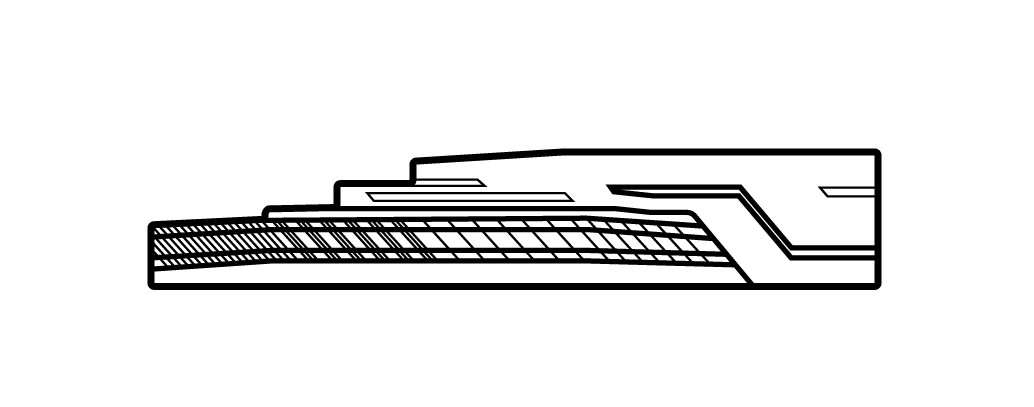

OMEGA 1 RUIFANG, TAIWAN

- Land Size

- AS/RS Zone

- Type of Storage

- Total Floor Area

- No. of Docks

- 32,000 sqm

- 8,700 pallet positions

- Cold chain

- 22,000 sqm

- 40 docks

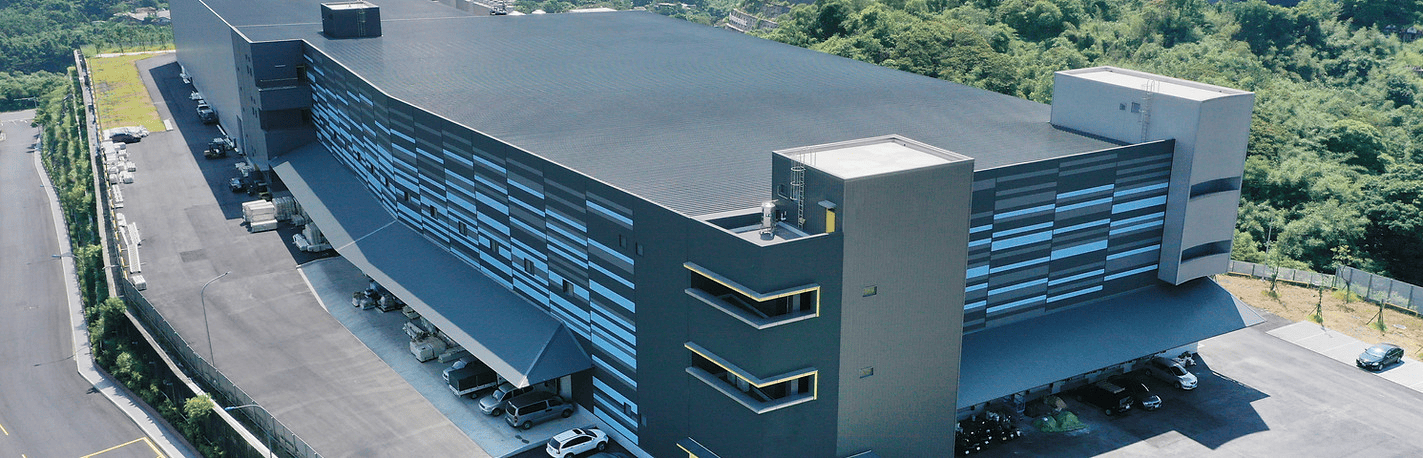

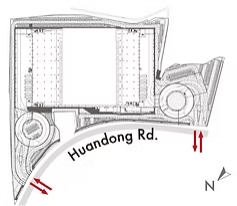

OMEGA 2 YANGMEI, TAIWAN

- Land Size

- AS/RS Zone

- Type of Storage

- Total Floor Area

- No. of Docks

- 64,000 sqm

- 80,000 pallet positions

- FMCG, Retailers, E-commerce platforms

- 134,000 sqm

- 180 docks

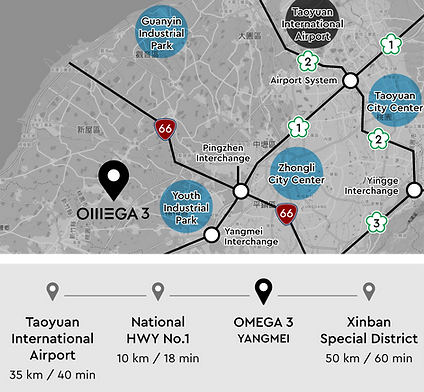

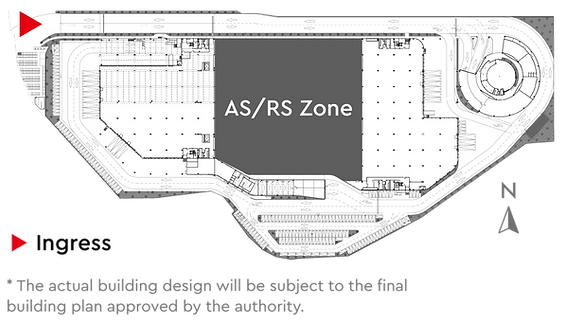

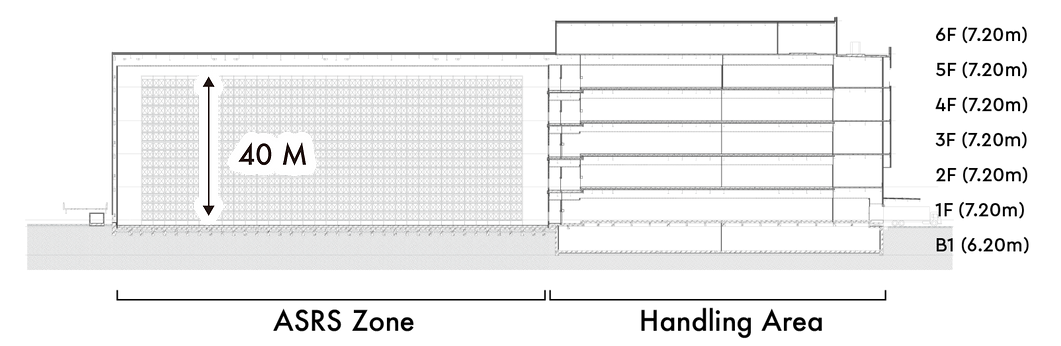

OMEGA 3 YANGMEI, TAIWAN

- Land Size

- AS/RS Zone

- Type of Storage

- Total Floor Area

- No. of Docks

- 51,000 sqm

- 65,000 pallet positions

- FMCG, Retailers, E-commerce platforms

- 78,000 sqm

- 120 docks

OMEGA 1 RUIFANG, TAIWAN

- Land Size

- AS/RS Zone

- Type of Storage

- Total Floor Area

- No. of Docks

- 31,000 sqm

- 20,000 pallet positions

- Cold chain, Retailers, E-commerce platforms

- 79,000 sqm

- 60 docks

OMEGA 1 RUIFANG, TAIWAN

- Land Size

- AS/RS Zone

- Type of Storage

- Total Floor Area

- No. of Docks

- 32,000 sqm

- 8,700 pallet positions

- Cold chain

- 22,000 sqm

- 40 docks

OMEGA 2 YANGMEI, TAIWAN

- Land Size

- AS/RS Zone

- Type of Storage

- Total Floor Area

- No. of Docks

- 64,000 sqm

- 80,000 pallet positions

- FMCG, Retailers, E-commerce platforms

- 134,000 sqm

- 180 docks

OMEGA 3 YANGMEI, TAIWAN

- Land Size

- AS/RS Zone

- Type of Storage

- Total Floor Area

- No. of Docks

- 51,000 sqm

- 65,000 pallet positions

- FMCG, Retailers, E-commerce platforms

- 78,000 sqm

- 120 docks

OMEGA 1 RUIFANG, TAIWAN

- Land Size

- AS/RS Zone

- Type of Storage

- Total Floor Area

- No. of Docks

- 31,000 sqm

- 20,000 pallet positions

- Cold chain, Retailers, E-commerce platforms

- 79,000 sqm

- 60 docks

OMEGA 1 RUIFANG, TAIWAN

- Land Size

- AS/RS Zone

- Type of Storage

- Total Floor Area

- No. of Docks

- 32,000 sqm

- 8,700 pallet positions

- Cold chain

- 22,000 sqm

- 40 docks

OMEGA 2 YANGMEI, TAIWAN

- Land Size

- AS/RS Zone

- Type of Storage

- Total Floor Area

- No. of Docks

- 64,000 sqm

- 80,000 pallet positions

- FMCG, Retailers, E-commerce platforms

- 134,000 sqm

- 180 docks

OMEGA 3 YANGMEI, TAIWAN

- Land Size

- AS/RS Zone

- Type of Storage

- Total Floor Area

- No. of Docks

- 51,000 sqm

- 65,000 pallet positions

- FMCG, Retailers, E-commerce platforms

- 78,000 sqm

- 120 docks

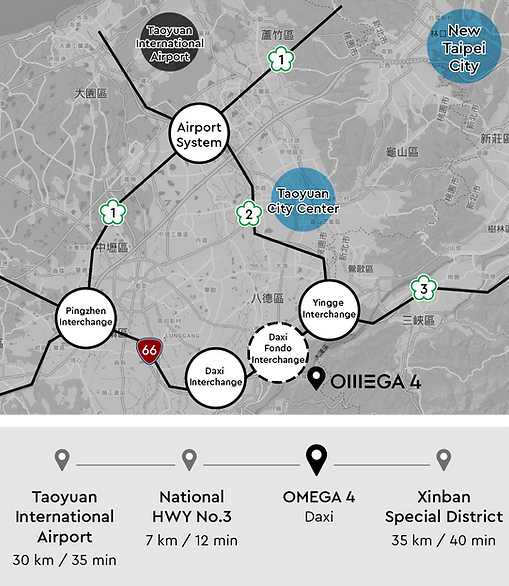

OMEGA 1 RUIFANG, TAIWAN

- Land Size

- AS/RS Zone

- Type of Storage

- Total Floor Area

- No. of Docks

- 31,000 sqm

- 20,000 pallet positions

- Cold chain, Retailers, E-commerce platforms

- 79,000 sqm

- 60 docks

OMEGA 1 RUIFANG, TAIWAN

- Land Size

- AS/RS Zone

- Type of Storage

- Total Floor Area

- No. of Docks

- 32,000 sqm

- 8,700 pallet positions

- Cold chain

- 22,000 sqm

- 40 docks

OMEGA 2 YANGMEI, TAIWAN

- Land Size

- AS/RS Zone

- Type of Storage

- Total Floor Area

- No. of Docks

- 64,000 sqm

- 80,000 pallet positions

- FMCG, Retailers, E-commerce platforms

- 134,000 sqm

- 180 docks

OMEGA 3 YANGMEI, TAIWAN

- Land Size

- AS/RS Zone

- Type of Storage

- Total Floor Area

- No. of Docks

- 51,000 sqm

- 65,000 pallet positions

- FMCG, Retailers, E-commerce platforms

- 78,000 sqm

- 120 docks

OMEGA 1 RUIFANG, TAIWAN

- Land Size

- AS/RS Zone

- Type of Storage

- Total Floor Area

- No. of Docks

- 31,000 sqm

- 20,000 pallet positions

- Cold chain, Retailers, E-commerce platforms

- 79,000 sqm

- 60 docks

OMEGA 1 RUIFANG, TAIWAN

- Land Size

- AS/RS Zone

- Type of Storage

- Total Floor Area

- No. of Docks

- 32,000 sqm

- 8,700 pallet positions

- Cold chain

- 22,000 sqm

- 40 docks

OMEGA 2 YANGMEI, TAIWAN

- Land Size

- AS/RS Zone

- Type of Storage

- Total Floor Area

- No. of Docks

- 64,000 sqm

- 80,000 pallet positions

- FMCG, Retailers, E-commerce platforms

- 134,000 sqm

- 180 docks

OMEGA 3 YANGMEI, TAIWAN

- Land Size

- AS/RS Zone

- Type of Storage

- Total Floor Area

- No. of Docks

- 51,000 sqm

- 65,000 pallet positions

- FMCG, Retailers, E-commerce platforms

- 78,000 sqm

- 120 docks

OMEGA 1 RUIFANG, TAIWAN

- Land Size

- AS/RS Zone

- Type of Storage

- Total Floor Area

- No. of Docks

- 31,000 sqm

- 20,000 pallet positions

- Cold chain, Retailers, E-commerce platforms

- 79,000 sqm

- 60 docks